HPES (Polyethersulfone)

HPES cartridges are made of casted sulfonated PES (Polyethersulfone) polymers.

This is designed for final filtration where absolute retention is required or final filtration to remove extremely fine particles

Features

Highly asymmetric pore structure

Inherently hydrophilic, good chemical compatibility

All materials meet FDA listed for food and beverages

Suitable for water treatment process

Applications

Pharmaceutical & Biological industry

Poto resists

General Industry

Electronic Industry (LCD / PDP / OLED / SOLAR CELL)

RO Final

Beverage Industry

Specification

| Dimension & Structure | OD | OD 63.5 / 65 mm |

| ID | ID 30 mm | |

| Length | 250mm(10") / 500mm(20") / 750mm(30") / 1,000mm(40") | |

| Materials of Construction | Media | Hydrophilic polyethersulfone membrane |

| Inner core | Polypropylene | |

| O-Ring & Gasket | Silicone, EPDM, Viton, TEV | |

| Type | DOE / 226 Flat / 222 Flat / 226 Fin / 222 Fin / EO | |

| Operating Conditions | Max. differential pressure | 36PSI / 2.5bar 60℃ |

| Max. operating temperature | 80℃ |

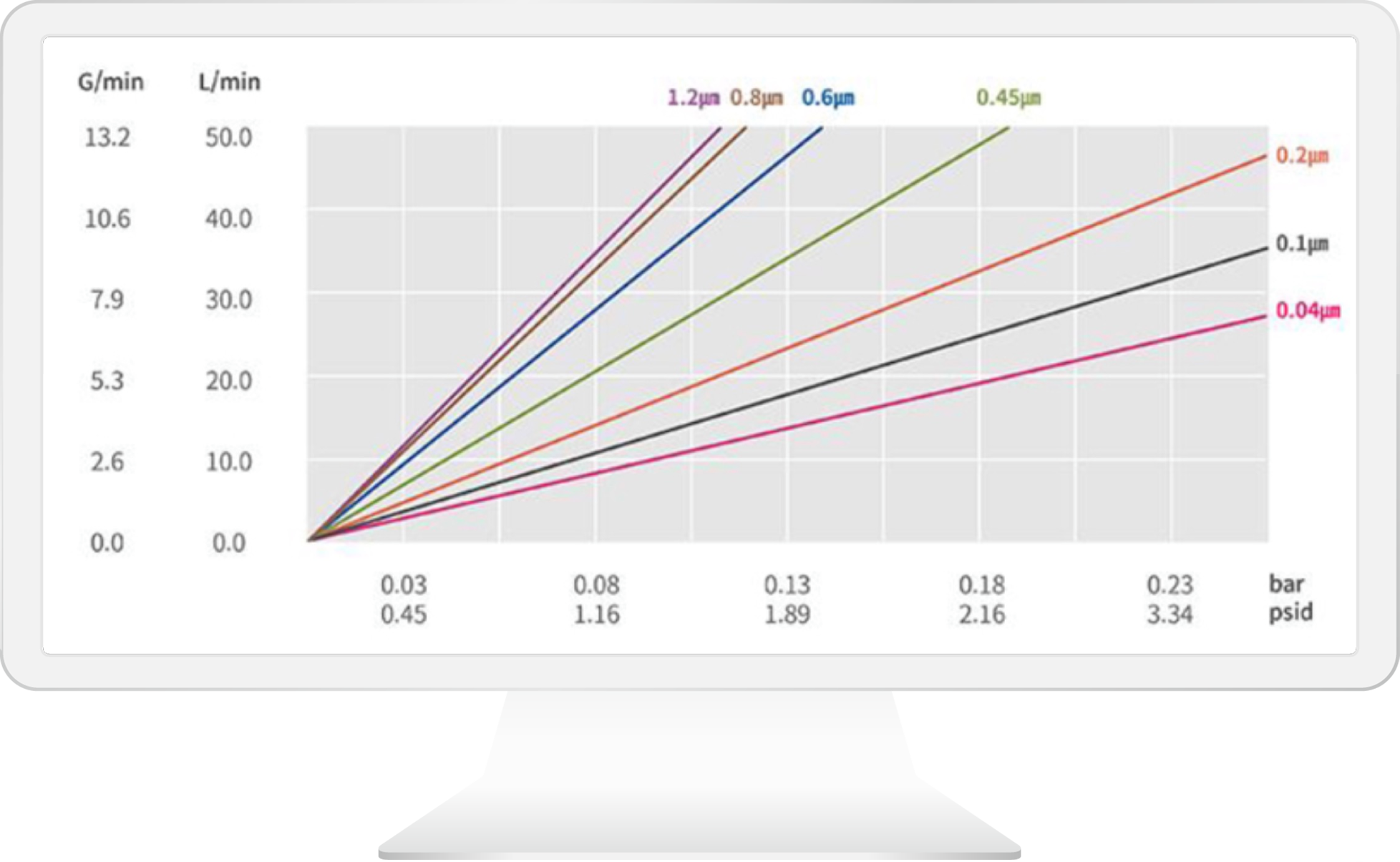

Pressure Drop (Flow Rate)

– 10 inch (250mm) Cartridge

Ordering Information

| HPES | - | - | - | ||||||

| Code-Size | Code-Micron | Code-Media | |||||||

| 210 | 6" x 20" | 001 | 0.1 | 01 | Polypropylene | ||||

| 220 | 6" x 30" | 002 | 0.2 | ||||||

| 230 | 6" x 40" | 004 | 0.45 | ||||||

| 240 | 6" x 20" | 006 | 0.6 | ||||||

| 008 | 0.8 | ||||||||

| 012 | 1.2 |