HW (STRING WOUND)

HW cartridges are wounded, each layer of roving is napped to increase filtration area and capabilities.

This is designed for applications when reliable and consisted depth filtration is required.

A broad range of media provides excellent chemical compatibility including chemicals, magnetic coatings,

food & beverage, oil production, air & gas etc.

Features

Conventional and classical type filter

Low maintenance cost

Suitable for high temperature and pressure process

Excellent chemical compatibility

Available in a wide range of materials

Available in a wide range of materials and micron ratings

Applications

Chemical Industry

Food & Beverage Industry

General Process Industry

Oil & gas Industry

Specification

| Dimension & Structure | OD | 63.5 / 110 mm |

| ID | 28 / 30 mm | |

| Length | 50mm(10") / 500mm(20") / 750mm(30") / 1,000mm(40") | |

| Materials of Construction | Media | Polypropylene, Polyester, Cotton, Fiber glass, Acryl |

| Inner core | Polypropylene / 304ss / 316ss | |

| O-Ring & Gasket | Silicone, EPDM, Viton, TEV & Foamed polyethylene | |

| Type | DOE / 226 Flat / 222 Flat / 226 Fin / 222 Fin / EO | |

| Operating Conditions | Max. differential pressure | 30 psid / 2.1 bar at 60℃ |

| 60 psid / 4.2 bar at 30℃ | ||

| Max. operating temperature | 304 SS, 316 SS core 140℃ | |

| PP core 80℃ |

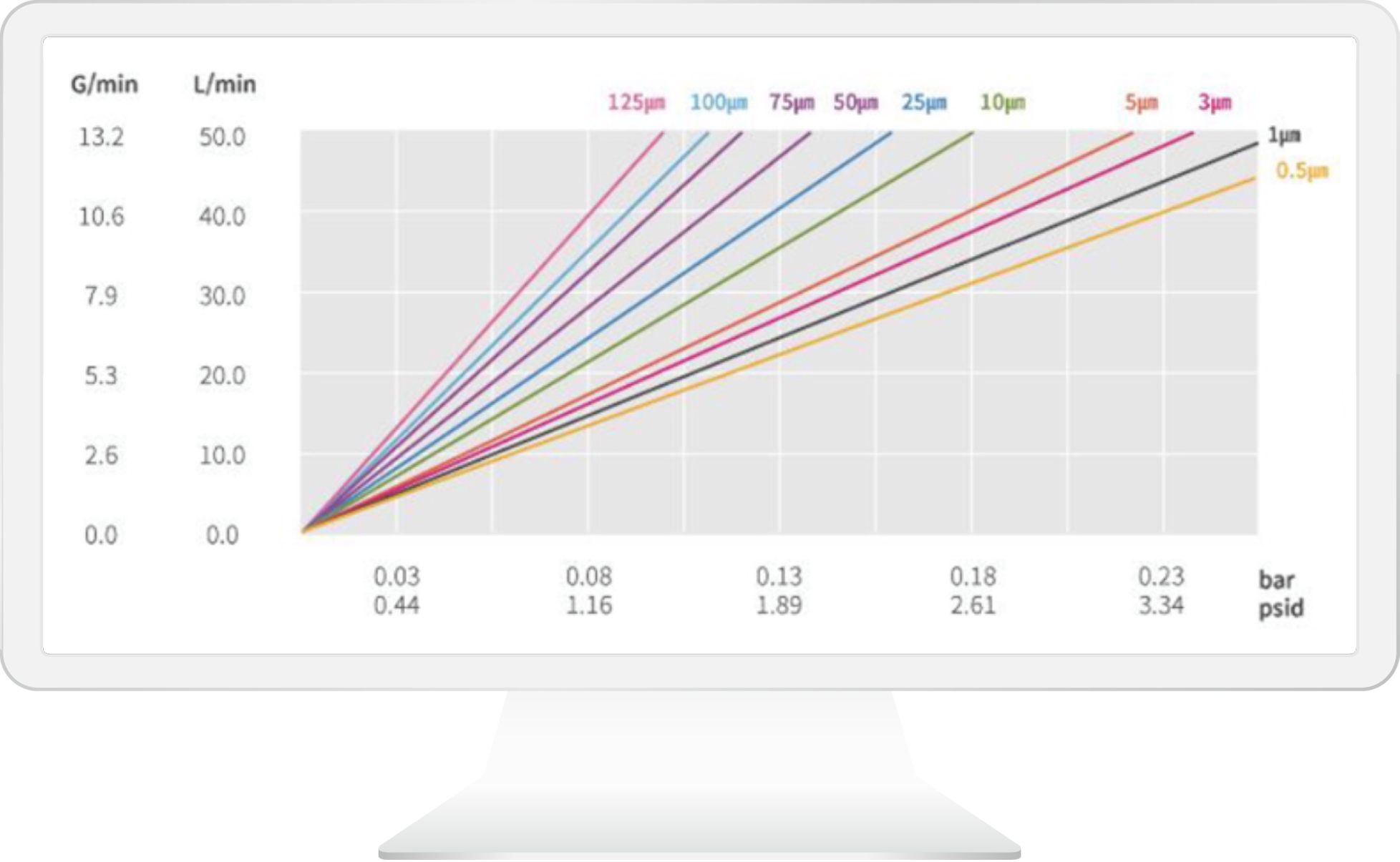

Pressure Drop (Flow Rate)

– 10 inch (250mm) Cartridge

Ordering Information

| HW | - | 230 | - | 010 | - | 001 | - | A | ||||

| Code-Size | Code-Micron | Code-Media | Code-Core | |||||||||

| 210 | 6" x 20" | 0005 | 0.5 | 001 | Polypropylene | A | PP | |||||

| 220 | 6" x 30" | 001 | 1 | 002 | Polyester | B | 304 SS | |||||

| 230 | 6" x 40" | 003 | 3 | 003 | Cotton | C | 316 SS | |||||

| 240 | 6" x 20" | 005 | 5 | 004 | Fiber glass | |||||||

| 410 | 6" x 30" | 010 | 10 | 005 | Acryl | |||||||

| 420 | 6" x 40" | 025 | 25 | |||||||||

| 430 | 6" x 20" | 050 | 50 | |||||||||

| 440 | 6" x 30" | 075 | 75 | |||||||||

| 1000 | 100 | |||||||||||

| 1250 | 125 |